Phone: 1-888-755-4370 (toll free US only)

Phone: 1-215-526-2151 (worldwide)

Email: info@www.advantapure.com

AdvantaSil® APHP is a platinum-cured silicone specifically engineered to meet critical pharmaceutical and biopharmaceutical high-pressure applications. Designed for high-volume fluid transfer, APHP stands out as the preferred material due to its higher durometer, providing superior pressure ratings compared to standard unreinforced tubing.

AdvantaSil® APHP is a platinum-cured silicone specifically engineered to meet critical pharmaceutical and biopharmaceutical high-pressure applications. Designed for high-volume fluid transfer, APHP stands out as the preferred material due to its higher durometer, providing superior pressure ratings compared to standard unreinforced tubing.

Its translucence allows for clear visibility of fluid flow making it an excellent choice for precise and efficient operations. APHP is rigorously validated, qualified, manufactured, and released under the most stringent product validation protocols, ensuring the highest quality and reliability for high-pressure, high-volume fluid transfer applications.

KEY FEATURES

- Compliant with USP <665> for extractables and leachables

- Translucent for fluid flow visibility while withstanding higher pressure

- 80A durometer for high pressure applications

- Higher durometer allows for greater pressure ratings than standard unreinforced tubing

- General temperature range -65°F (-53.9°C) to 400°F (204.4°C)

- Custom lengths, sizes and packaging available

- Manufactured with a focus on sustainability

- Excellent for applications that require processing at higher flow rates

- Produced, assembled and packaged in an ISO Class 7 cleanroom

- Sterilized by autoclave and via gamma irradiation

- Security of supply chain with redundant manufacturing sites

- Wide range of sizes from 0.125" to 1.5" (3.18 mm to 38.1 mm) ID

- Comprehensive validation package available upon request to expedite qualification and validation, including full extractables report (BPOG)

- Now available as mini and standard Tri-Clamp® ends — call for details!

Full BPOG standardized extractables test results available on request

ATTENTION:

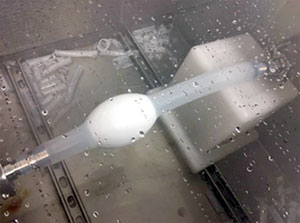

Specific cutting techniques are strongly recommended for AdvantaSil APHP High Pressure Silicone Tubing. APHP must be cut with a chevron style cutter at a 90 degree angle to the tubing, leaving a smooth, non-jagged, perpendicular cut at the tubing end. View cutter product details and purchase information at https://www.lislecorp.com/specialty-tools/hose/hose-cutter. See our cutting technique video below.

SPECIFICATIONS

APHP - HIGH PRESSURE SILICONE TUBING

Dimensional Specifications

| Product Number | Nominal I.D. | Wall | O.D. | Bend Radius | Standard Available Lengths | ||||

| (in.) | (mm) | (in.) | (mm) | (in.) | (mm) | (in.) | (mm) | (ft.) | |

| APHP-0125-0250 | .125 | 3.18 | .063 | 1.60 | .250 | 6.35 | .375 | 9.5 | 50 |

| APHP-0250-0375 | .250 | 6.35 | .063 | 1.60 | .375 | 9.52 | 1 | 25 | 50 |

| APHP-0375-0625 | .375 | 9.52 | .125 | 3.18 | .625 | 15.88 | 1.2 | 30 | 50 |

| APHP-0500-0750 | .500 | 12.70 | .125 | 3.18 | .750 | 19.05 | 1.8 | 46 | 50 |

| APHP-0750-1000 | .750 | 19.05 | .125 | 3.18 | 1.000 | 25.40 | 2.1 | 53 | 50 |

| APHP-1000-1375 | 1.000 | 25.40 | .188 | 4.76 | 1.375 | 34.93 | 4.1 | 104 | 50 |

| APHP-1500-1875 | 1.500 | 38.1 | .188 | 4.76 | 1.875 | 47.6 | 6 | 152 | 10 |

Performance Specifications

| Product Number | Burst Pressure Non-Treated | Recommended Working Pressure based on 3:1 safety factor Non-Treated | Burst Pressure Gamma Irradiated 45kGy | Recommended Working Pressure based on 3:1 safety factor Gamma Irradiated 45kGy | Vacuum Capability | ||||

| (psi) | (bar) | (psi) | (bar) | (psi) | (bar) | (psi) | (bar) | (in./Hg) | |

| APHP-0125-0250 | 175 | 12.1 | 58 | 4.0 | 184 | 12.7 | 61 | 12.7 | >29.5 |

| APHP-0250-0375 | 109 | 7.5 | 36 | 2.5 | 127 | 8.8 | 42 | 2.9 | >29.5 |

| APHP-0375-0625 | 168 | 11.6 | 56 | 3.9 | 182 | 12.5 | 61 | 4.2 | >29.5 |

| APHP-0500-0750 | 124 | 8.5 | 41 | 2.8 | 138 | 9.5 | 46 | 3.2 | >29.5 |

| APHP-0750-1000 | 103 | 7.1 | 34 | 2.3 | 113 | 7.8 | 38 | 2.6 | >29.5 |

| APHP-1000-1375 | 76 | 5.2 | 25 | 1.7 | 105 | 7.2 | 35 | 2.4 | >29.5 |

| APHP-1500-1875 | 83 | 5.7 | 27 | 1.9 | 91 | 6.3 | 30 | 2.1 | >29.5 |

Sold by standard coil length of 50 ft. Add length suffix code "L" to product number when ordering. Example: 50 ft. of .250 in. I.D. x .375 in. O.D. tubing is product number APHP-0250-0375L. Non-listed sizes and custom lengths available by special order. Coils are supplied double bagged in heat-sealed polybags and bulk packed. Contact your AdvantaPure Sales Representative regarding any special product or packaging needs. Recommended working pressures are calculated from burst testing using a 3:1 safety factor. Testing was performed at ambient temperature. Application testing is recommended. CF = Consult factory The 1.5” APHP is compatible with Abec Bioreactors , CPC Aspectic Connectors , and T and Y Connectors from Nordson NOTE: The data listed throughout this web site is meant only as a guide to aid in design, and is believed to be reliable; however, nothing stated shall constitute a guarantee or warranty for any application. Product field-testing should be performed to find the actual values for a specific application. |

APHP CASE STUDY AVAILABLE

This case study describes the performance of AdvantaSil High Pressure Unreinforced Silicone Tubing (APHP) used in a Monoclonal Antibody process for the transfer of buffers in purification.

![]() Download a printable version of our High Pressure Tubing brochure. AdvantaSil_High_Pressure_Tubing.pdf (163kb)

Download a printable version of our High Pressure Tubing brochure. AdvantaSil_High_Pressure_Tubing.pdf (163kb)

![]()

APHP CASE STUDY AVAILABLE

This case study describes the performance of AdvantaSil High Pressure Unreinforced Silicone Tubing (APHP) used in a Monoclonal Antibody process for the transfer of buffers in purification.

SINGLE-USE SYSTEMS

Single-use Systems are custom made using AdvantaSil® platinum-cured, Class VI silicone tubing and hose or AdvantaFlex® Class VI biopharmaceutical grade tubing. Add fittings, stoppers and container closures, filters, bottles, labels and tracking options, and other components.

| Home | Products | News & Events | About Us | Find a Distributor | Information Request | Contact Us |

| Tubing & Hose | Fittings & Clamps | Single-Use Systems | Molded Products | Custom Products & Services | Hose Identification |

| Product Videos

| Legal Notices & Trademarks | Terms & Conditions of Sale | Privacy Policy | Feedback/Questions | Site Map |

AdvantaPure products are produced by NewAge® Industries, Inc., 145 James Way, Southampton, PA 18966 USA

Phone: 215-526-2151 • 888-755-4370 (toll free US only); Fax: 215-526-2167 • 888-258-4293 (toll free US only); Email: info@www.advantapure.com

©2001-2021 NewAge® Industries, Inc. All rights reserved worldwide.