AdvantaPass®

Clean Room Pass-Through Technology

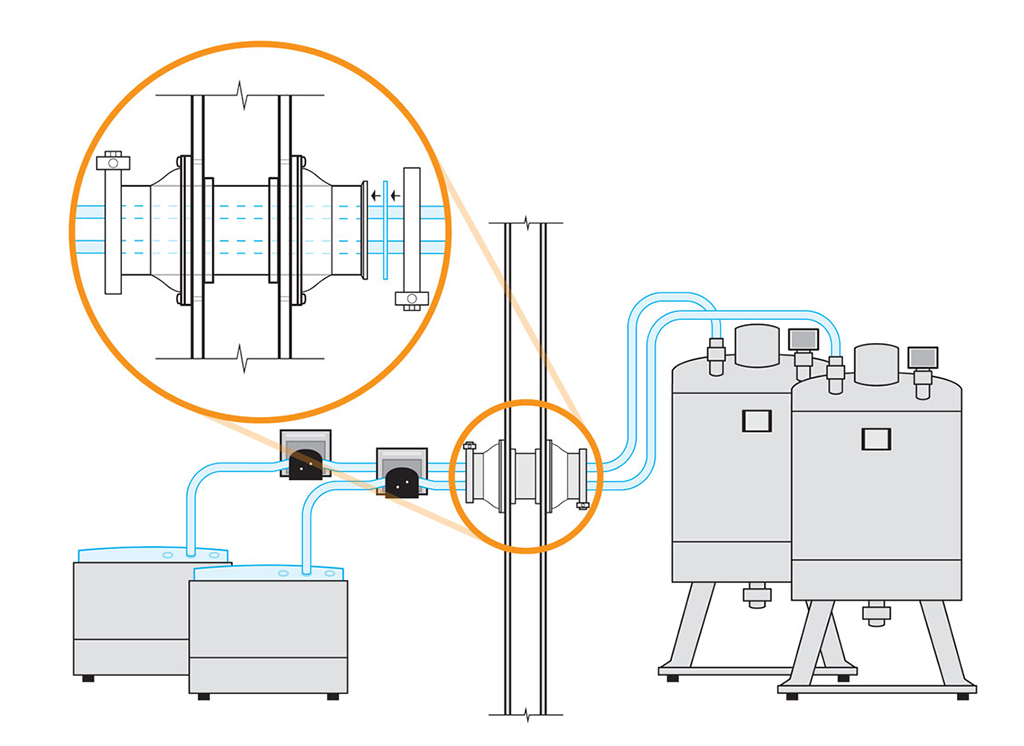

AdvantaPure’s patented AdvantaPass design facilitates aseptic fluid transfer between the cleanroom and bulkhead utilizing the wall between them. Whether using single-use systems (SUS) or another tubing or hose, the AdvantaPass consistently provides a safe, easy to use fluid transfer option.

Key Features & Benefits

- When used with SUS components – eliminates the need to clean and validate hard piping

- Single or multiple fluid flow lines without isolation barrier compromise

- Provides reliable fluid transfer method without the need to reconfigure surrounding space

- Low maintenance

- Custom manufactured base unit, standardized complementary parts per application

- Compatible with most wall and floor thicknesses

- Assembly takes minutes

- Standard sizes 4” and 6” with custom configurations available

- Port assembly made in the USA from 316L stainless steel

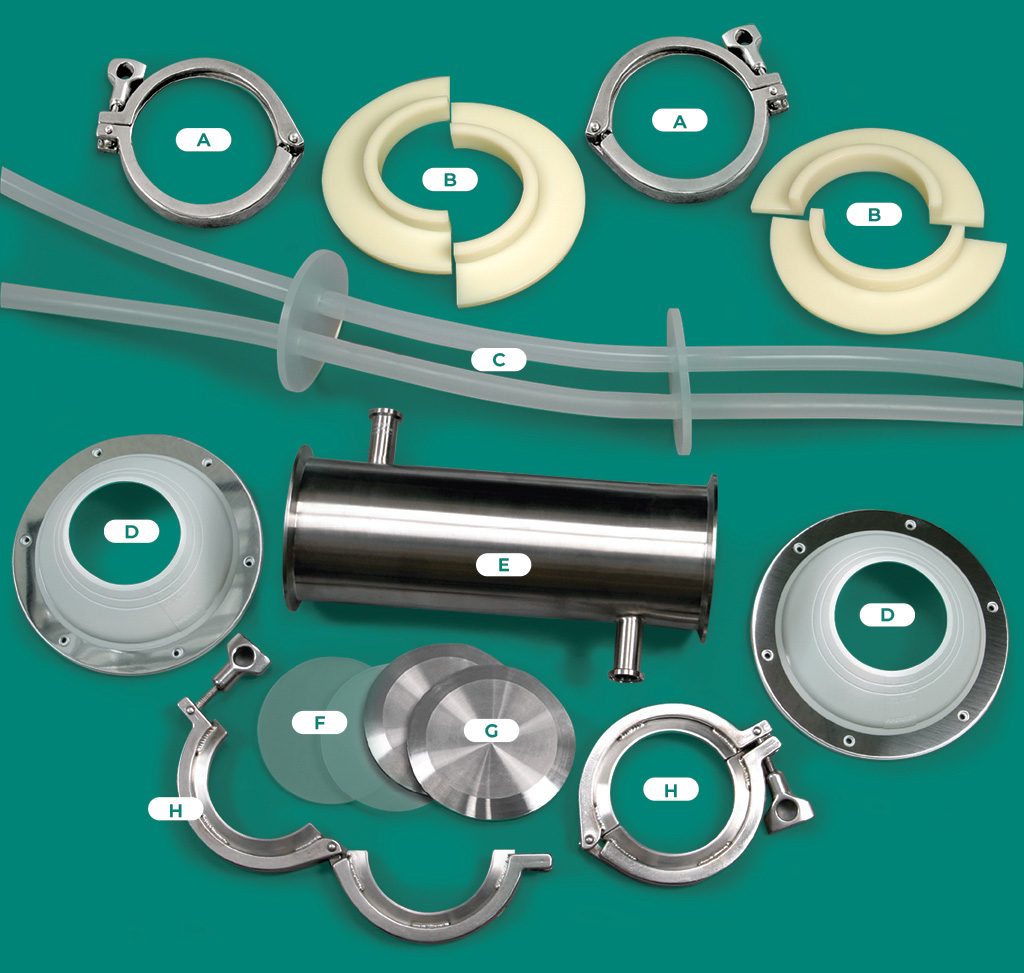

AdvantaPass Components

A – Hygienic Clamp HD 304 SS

Select The Right AdvantaPass

Choose Your AdvantaPass Base Unit (based on purge port and wall size)

4" Portals

| Part Number | Description | Purge or No Purge | Wall Size |

|---|---|---|---|

| A8902109 | ADVANTAPASS 4” 316L SS PORTAL | PURGE PORT | 1.5” to 4” |

| A8902122 | ADVANTAPASS 4” 316L SS PORTAL | PURGE PORT | 4” to 6” |

| A8902135 | ADVANTAPASS 4” 316L SS PORTAL | PURGE PORT | 6” to 8” |

| A8902564 | ADVANTAPASS 4” 316L SS PORTAL | W/O PURGE PORT | 1.5” to 4” |

| A8902577 | ADVANTAPASS 4” 316L SS PORTAL | W/O PURGE PORT | 4” to 6” |

| A8902590 | ADVANTAPASS 4” 316L SS PORTAL | W/O PURGE PORT | 6” to 8” |

6" Portals

| Part Number | Description | Purge or No Purge | Wall Size |

|---|---|---|---|

| A8902200 | ADVANTAPASS 6” 316L SS PORTAL | PURGE PORT | 1.5” to 4” |

| A8902213 | ADVANTAPASS 6” 316L SS PORTAL | PURGE PORT | 4” to 6” |

| A8902226 | ADVANTAPASS 6” 316L SS PORTAL | PURGE PORT | 6” to 8” |

| A8902655 | ADVANTAPASS 6” 316L SS PORTAL | W/O PURGE PORT | 1.5” to 4” |

| A8902668 | ADVANTAPASS 6” 316L SS PORTAL | W/O PURGE PORT | 4” to 6” |

| A8902681 | ADVANTAPASS 6” 316L SS PORTAL | W/O PURGE PORT | 6” to 8” |

Purge Port Sealing Options

Choose a Purge Port Sealing Option (when choosing this option all items below must be ordered)

| Part Number | Description |

|---|---|

| A7300059 | PLATINUM SILICONE GASKET FOR – 3/4″ MINI TRI-CLAMP |

| CA7391151 | SANITARY FITTING MINI END CAP |

| CA7921177 | SANITARY NYLON CLAMP .750″ |

Customizable Manufacturing

This system reduces production stoppages associated with sterilization and validation of hard piping transfer systems, saving resources, cleaning chemicals, time, and labor. The single-use components offer flexibility, minimize cross-contamination risk, and improve productivity and efficiency.

Download a printable version of our AdvantaPass brochure

Is AdvantaPass right for me?

Suggested Additional Components

AdvantaFlex Biopharmaceutical Grade TPE Tubing

AdvantaFlex provides a flexible, sterilizable, moldable, weldable, and heat sealable biopharmaceutical tubing without silicone oils. It maintains its physical properties, including its translucence, following sterilization and does not become “gummy”. All tubing is kink resistant.

Single-Use Isolator Assembly

A single-use isolator assembly can be manufactured to fit the AdvantaPass and includes either the AdvantaSil (APST) or AdvantaFlex (APAF-BP) tubing. All assemblies include silicone, friction fit isolator disks. This assembly supports multiple tubes passing through the isolator disk and allows for a customizable mix of silicone and TPE to meet your specific needs.