BIOTECH TALK

The Advantages of Choosing Overmolding and Molded Manifolds for Your Process

By Field Applications Specialist, Kendall V. Horst, MSc

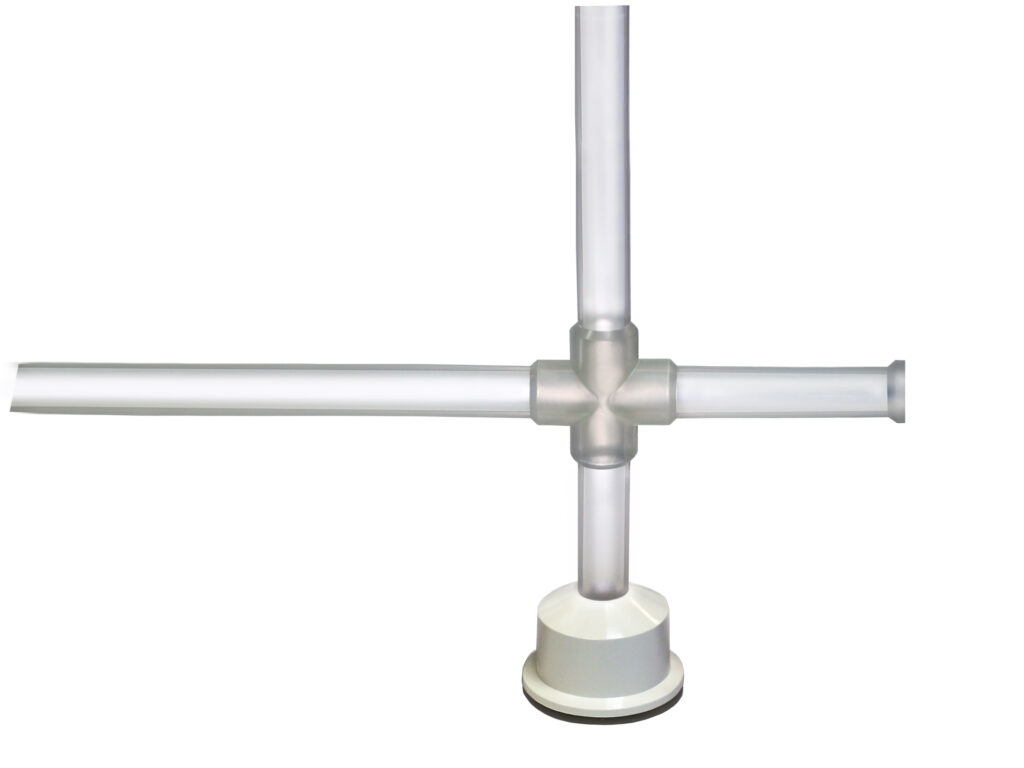

In the bioprocess industry, the adoption of overmolding for manifolds can provide many measurable benefits. Overmolding refers to the process of molding thermoplastic or thermoset material over connectors or tubing, creating seamless, robust connections between tubing and components. In bioprocessing, manifolds are custom-designed assemblies that connect multiple tubing lines into a single, unified product and using overmolding reduces risks associated with connectors. Overmolding is a specialized area of injection molding.

Together, the result surpasses traditional leak-prone assemblies by providing integrated, sealed units that enhance the reliability and integrity of single-use bioprocess systems. Overmolding and molded manifolds provide multiple benefits that include but are not limited to:

Key Benefits

- Enhanced Sterility and Contamination Control

- Reduces the need for components like barbed fittings and hose clamps.

- Creates a more seamless flow path, reducing dead spaces and potential microbial

ingress points. - Ideal

for aseptic operations such as media and buffer preparation, sterile

filtration, and final fill.

- Reduced Assembly Errors

- Molded configurations minimize time and labor associated with manual fabrication.

- Increases product consistency and manufacturing repeatability.

- Reduces chances of incorrect installation during setup, improving operator safety and process repeatability on the drug manufacturing floor.

- Accelerated Installation and Turnaround

- Plug-and-play designs simplify equipment setup, enabling rapid changeovers in multi-product facilities.

- Improved Integrity and Validation

- Overmolded joints are leak-proof and pressure-tested, reducing the risk of batch loss.

- Smoother

inner bores reduce cell shear and entrapment, to improve cell viability.

- Customized configurations for specific applications based

on user requirements such as:- Upstream: Feed line manifolds for media or buffer delivery and drug substance.

- Downstream: Sample collection or pooling manifolds in filtration or purification

steps. - Final fill: Sterile filling manifolds with multiple filling needles or vessels.

Suggested Applications and Benefits

Media/Buffer Preparation

Sterile and leak proof connections

Bioreactor Process Lines

Simplified configurations, quick changeover, lower sheer

Clarification/Harvest

Contamination reduction

Chromatograhy/TFF

Robust pressure handling, lower shear

Final Fill

Contamination reduction

Conclusion

Overmolding is transforming how bioprocess systems are designed and operated. By utilizing high-quality manifolds that are precisely designed and manufactured, they reduce system complexity and enable faster, safer operations.

Manifolds that are overmolded support the industry shift toward using single-use systems for flexible manufacturing while minimizing batch loss and maintaining system integrity.

For companies seeking to scale efficiently while mitigating risk, adopting molded solutions is no longer just an option but a strategic advantage in the evolving definition of cGMP drug manufacturing.

Download a printable version of this BIOTECH TALK ARTICLE