Engineering Capabilities

NewAge Industries and AdvantaPure have increased their engineering capabilities with the aim of providing better and faster services to our customers.

AdvantaPure’s Engineering team consists of Applications Engineers, Design and Test Engineers, Engineering Project and Process Managers, and Tooling Engineers. Their technical experience combined with a broad range of engineering backgrounds gives our team the expertise necessary to meet the needs of the industry.

Project Management

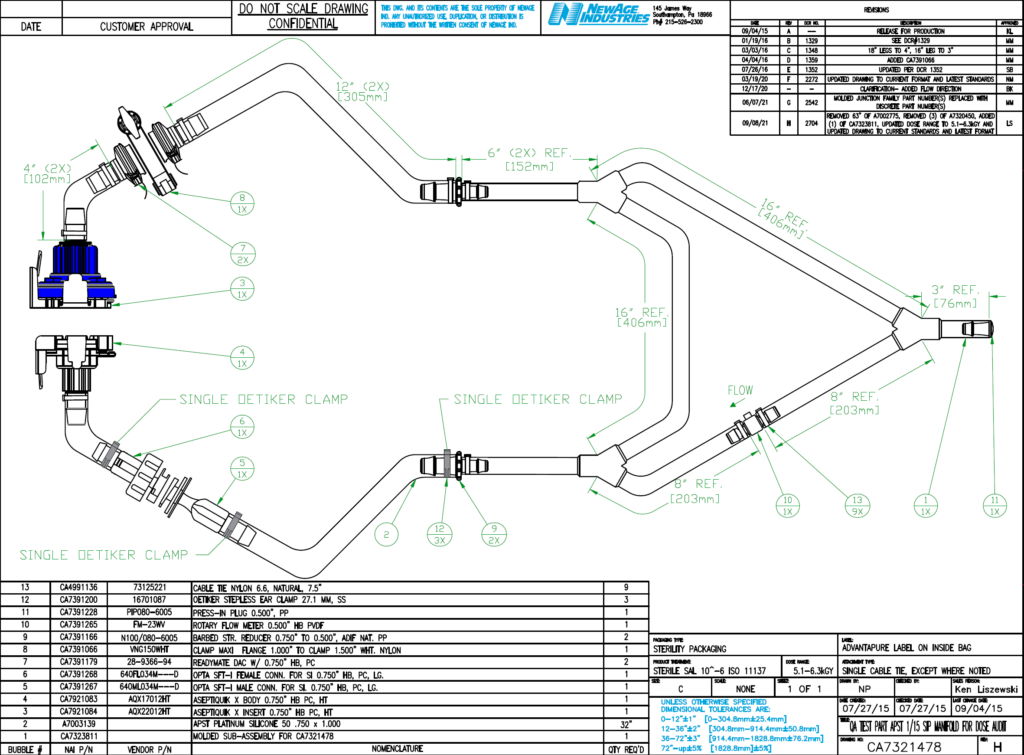

The project management team, located within our engineering department, is focused on new product development and managing all phases of new product launches, line extensions, and potential project solutions. When new, application-specific designs and custom manifolds are required to meet the ever-evolving needs of the biopharma industry, our project management team is ready to help guide the project through from idea and concept all the way to testing and production. The team uses the robust and efficient Stage-Gate® process for new product development. Projects are carefully managed to ensure that all critical steps are taken throughout the development process, and customers can speak directly with an engineer for assistance.

Tooling Design & Development

Applications Engineering

Product Testing

AdvantaPure’s product testing team has a staffed test facility with many capabilities, including but not limited to:

- Peristaltic Pump Life and Spallation Testing

- Tensile Testing

- Adhesion Testing

- Leak Detection Testing

- Weld and Seal Testing

- Burst Pressure Testing

- Hardness Testing

- Package Puncture, Tear, and Integrity Testing

- Testing of Products at a Wide Range of Temperatures

- Statistical Data Collection and Analysis

- Custom Testing of Overmolded Junctions and Sanitary Ends

- Custom Test Protocol Design, Execution and Reporting

Other testing may be outsourced for sterility, validation and physical property requirements concerning the hardness or softness of materials, dimensions and mechanical data.